Quick Service & Work, We Assist You 24/7

Drawing upon our years of experience, we offer a diverse range of pipe rotators. Our rotators are engineered to fully rotate large offset loads for pipe spooling and welding applications that demand precise positioning and mechanization

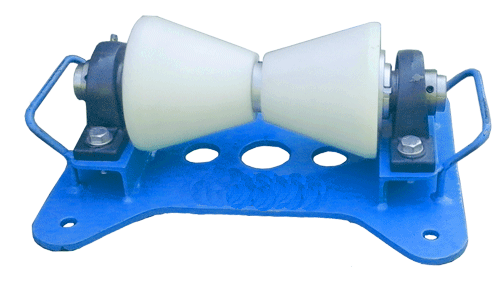

SPM PIPE ROTATORS are utilized to aid in the welding process of pipes, containers, tanks, and vessels as they stabilize and rotate heavy cylindrical objects. The rotator is equipped with turning rolls that can be adjusted to the size of the cylinder, keeping it in position while it is being welded.

A manual pipe rotator only includes idle rollers, whereas an automatic welding rotator has both an idle and a powered section. Self-aligning pipe rotators can automatically adjust to the size and shape of the object being placed and during the welding process. This eliminates the need for manual handling and can even handle oval and asymmetrical shapes.

Features :

- Maintaining a stable and consistent turning speed for unwieldy connections.

- Available in 2″ to Above sizes.

- Minimize the risk of damage by reducing the need for lifting and shifting.

- Exhibiting exceptional strength and longevity.

- Superior finishing.

- User-friendly in terms of operation and storage.

- The design is sturdy and able to withstand heavy use.