Quick Service & Work, We Assist You 24/7

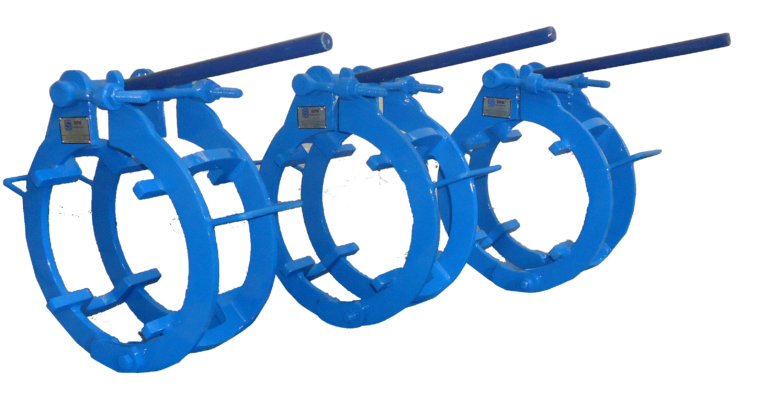

PIPE WELDING PNEUMATIC CLAMP

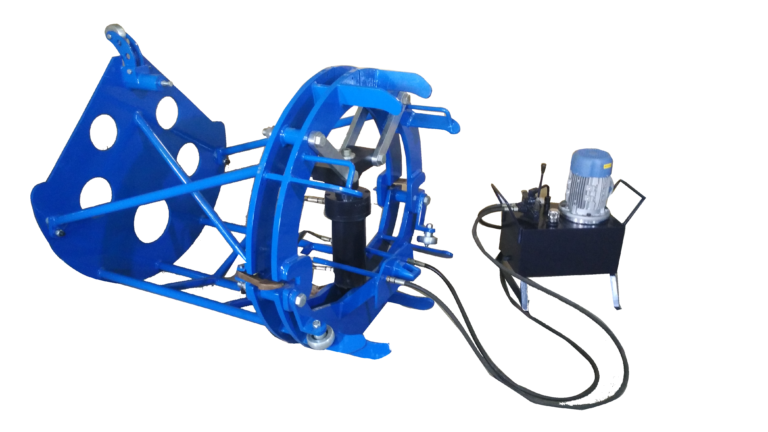

SPM Pipe Welding Pneumatic Clamp is extremely robust and built to special high standards to withstand pipeline spread operations. Clamps are adjustable for any wall thickness or size within the specified range—independently operated pneumatic jaws allow the line-up of pipes with different wall thicknesses. When correctly used pipe welding pneumatic clamp will not damage or “bell end” the pipe.

Pipe welding pneumatic clamp travels through the pipe to the next joint under its own power. Pipe welding pneumatic clamp require compressed air at 100-145 psi (7-10 bars). Maximum safe working pressure is 175 psi (12 bars).

Features:

- Pipe Welding Pneumatic Clamp covers a range of diameters and is adjustable for wall thicknesses within the specific range.

- Pneumatic Pipe Welding Clamp is adjusted to the require setting by SPM according to the pipe wall thickness.

- Pneumatic Pipe welding Clamp requires flattens air pressure from a compressor.

- Alloy Steel wheels provided with clamps for smooth travelling.

- SPM Pneumatic Pipe Welding Clamp is exemplary choice for construction of oil and natural gas pipeline.

- Separately operated Pneumatic jaws allow the line of pipes with different wall thicknesses.

- Adequate line up at the next joints is assured by a reserve air tank.

- Conversion kits for various pipe sizes are available upon request.

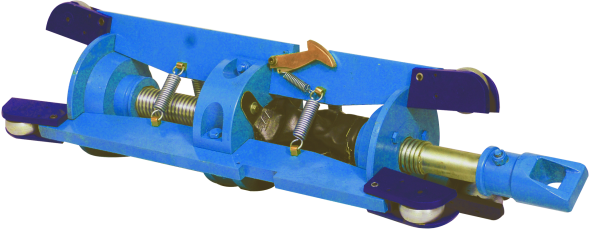

- The Internal Line up Clamp Pneumatic works inside the pipe. Roller-type actuating jaws hold the pipe ends to assure an adequate alignment of two pipe joints for external welding.

- Available in size 16” to 64” and upper size available on request.

- Pneumatic Pipe Welding Clamp can cover two sizes between 16” to 64” with use of conversion kit.

- Conversion kits are available for various sizes on request.